Coated Diamond/CBN

Electroless Ni Coat

Improve the mechanical retention of diamond or CBN, providing better heat dissipation, long use life and smooth surface finish.

Suitable for resin bonded system.

30%, 56%, 60% coated (by weight) available

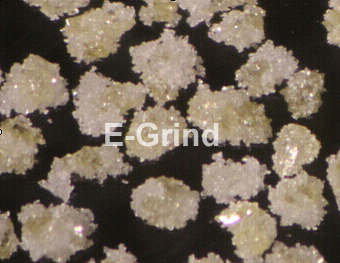

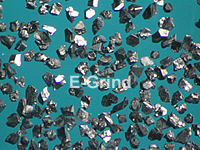

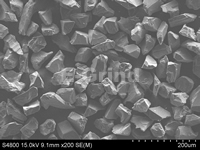

Electroless Ni Coated (EA-R11 Ni56) |

Electroless Ni Coated (EA-R11 Ni56) |

Electroless Ni Coating

Electrolytic Ni coat

Enhances the mechanical retention of diamond or CBN, provide better heat dissipation, higher grinding efficiency and longer using life to tools.

Suitable for resin bonded system.

30%, 56%, 60% coated (by weight) available

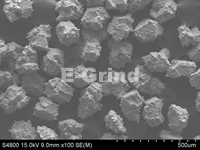

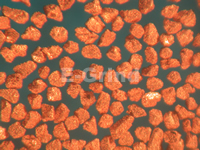

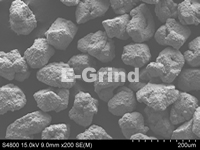

Electrolytic Ni Coated (EA-M40 Ni56) |

Electrolytic Ni Coated (EA-M40 Ni56) |

Electrolytic Ni Coating

Titanium-Coated

Prevent diamond or CBN grits from oxidation and graphitization at high temperature; Greatly improve the retention of diamond or CBN and tool life.

Suitable for Resin Bond and Metal Bond system

2% coated (by weight) available

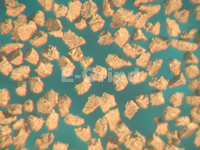

Titanium coated (EA-M40 Ti) |

Titanium coated (EA-M40 Ti) |

Copper-Coated

Recommended in dry grinding applications. Improves the retention of diamond or CBN and provide excellent heat dissipation.

Suitable for Resin bond system

50% coated (by weight) available

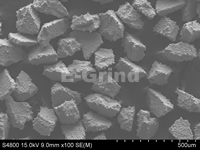

| Copper Coated (EA-R23 Cu50) |

Copper Coated (EA-R23 Cu50) |

Ceramic-Coated

The diamond or CBN grits with ceramic-coating will have better performance in cutting efficiency, toughness, and self-sharpening. It provides diamond or CBN with better retention with bond. Thus the tools will have longer using life. Meanwhile it avoids loading up during grinding process.